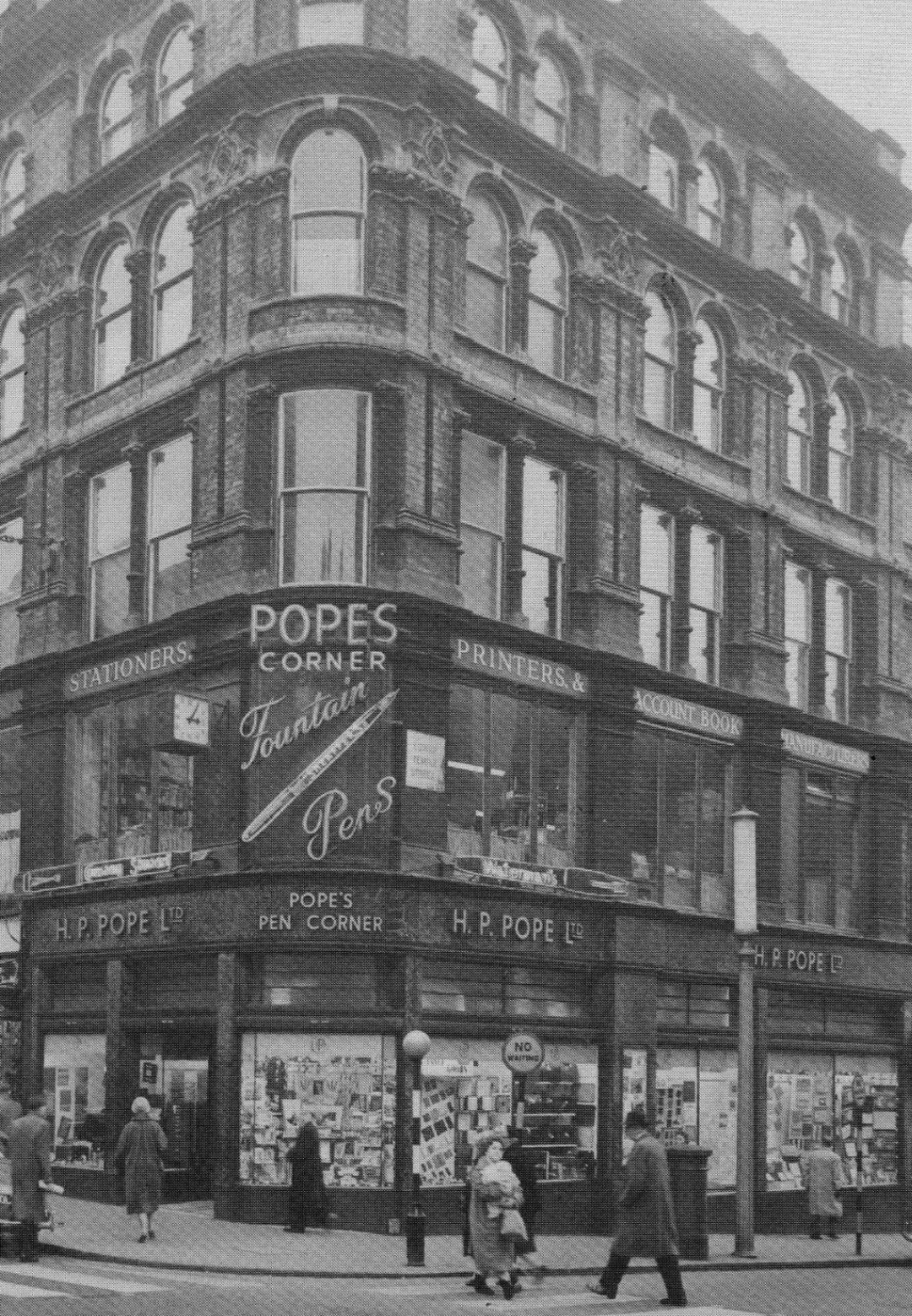

One of my recent Parker 17 acquisitions from eBay included the original box and user guide. On this, the purchase date of 22-10-66 had been written, and an ink stamp read “H.P.Pope Ltd, Pope’s Pen Corner, 114 New Street, Birmingham.”

As I was due to visit Birmingham, I was keen to see whether this pen shop still existed, 57 years on. An online search using instant streetview showed the building but the site was now occupied by Starbucks. I found an old image of the fountain pen shop. I still went to find the site, feeling pleased with my detective work.

However, during my two day visit, I discovered that Birmingham’s pen history contains rather more than that, to say the least. The city map shows a Jewellery Quarter, which includes a Pen Museum. Fortunately it was open. The Museum is located in a former pen factory, on Frederick Street. This particular one was the premises of W.E.Wiley, gold pen makers. I learned that the large scale production of steel pens, or what I call dip pens, had flourished in the nineteenth century, particularly from around the 1820’s.

There was a lot of information to take in, from the displays in the Museum, spread across three large rooms. The figures were staggering. As the industry grew to a worldwide export trade, there were at one time 129 pen manufacturers in Birmingham, producing 75% of all the pens in the world! The industry employed 8,000 people in Birmingham, and a large proportion were women operating the hand presses to carry out the various steps in producing a nib, or other tasks such as grinding, or “looking over” which we now call quality control.

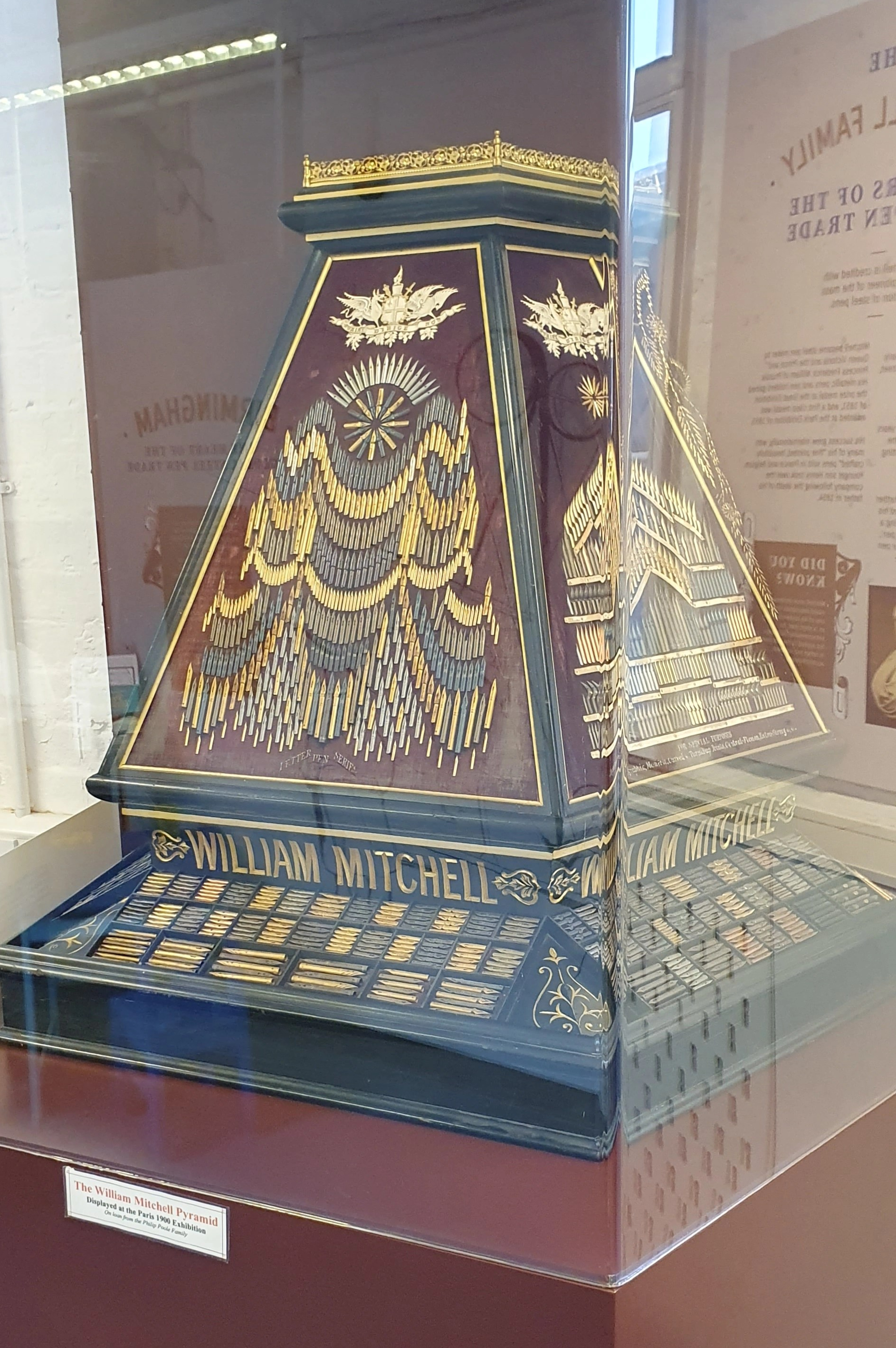

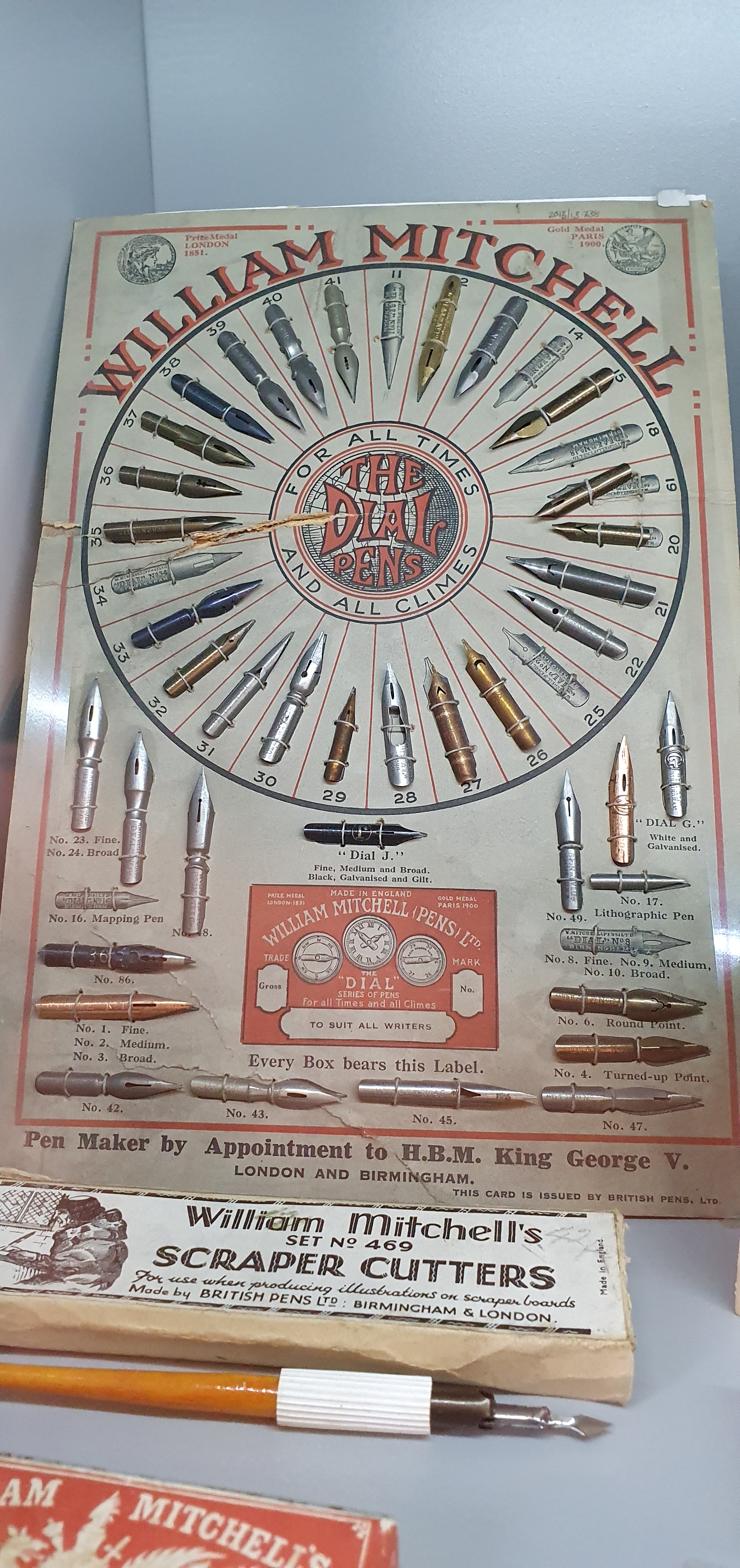

Hundreds of different types of nibs were made. We saw the Hinks, Wells & Co Star, from the 1866 Birmingham exhibition, showing nibs from the company’s stock of pens in daily use at that time. The museum also contains The William Mitchell Pyramid, shown at the Paris 1900 Exhibition.

A helpful guide showed us a few of the stages involved in producing a pen, such as

- Blanking: where a sheet of steel is fed through a press and, one by one, the operator punched plain blanks, or flat pieces of steel to form the nib;

- Piercing: where another press punches a hole in the nib; this is to add elasticity and to prevent the slit (added later) from extending further, as well as for ornamentation;

- Stamping, or Marking: where text is pressed into the pen;

- Raising: where another press forms the blank into a curved shape;

- Slitting: where a press cuts a slit, to form two tines.

We had an opportunity to try our hand at these stages and to make our own nib. There is some skill involved in operating the press with the right amount of force to get legible text. Getting the hole in the middle is not as easy as you might think. I found Slitting to be particularly fiddly and awkward. As there was space for the pen to move from side to side, it was difficult to ensure that the slit would be central. Mine was not. We had been warned of the risk of spoiling our nib at this stage and that we could skip it if we wished. Happily, our guide later gave us each a good one as a souvenir, at the end of the demonstration.

Having spent a few minutes trying out these vintage presses at a leisurely pace, it was a shock to learn that a woman operating a press was expected to make 18,000 nibs in a 10 hour day. This is one every 2 seconds. It would take me several seconds just to pick up a blank from the heap on the workbench, then several seconds more to position it centrally in the press and get my fingers out of the way, before pulling the heavy handle. I suppose they got very fast with practice, but imagine how tiring and monotonous it must have been, doing that all day, every day.

The Museum is mostly concerned with steel dip pens although there were a few vintage fountain pens on display, as well as ink bottles, tins and boxes, advertisements, signage and other memorabilia.

It was news to me that Birmingham played such an important role in the history of pen making. Although this provided employment and enabled the entrepreneurs to become very wealthy, this new, large scale production of pens at low cost, including for schools, was very important in improving literacy around the world.

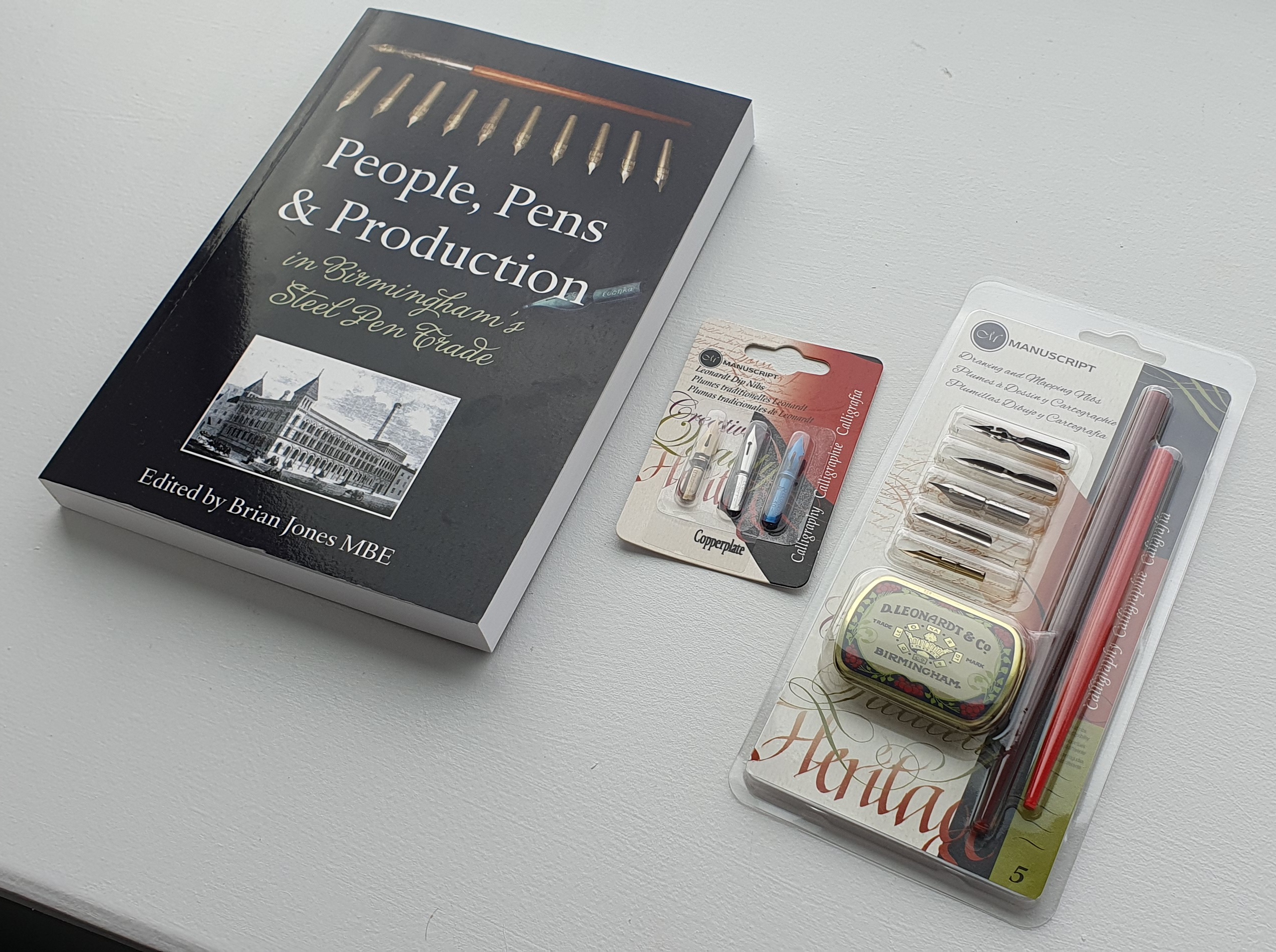

The story of Birmingham’s past as a world leader in pen manufacture, is told in an authoritative book “People, Pens & Production in Birmingham’s Steel Pen Trade”, edited by Brian Jones MBE, which I bought in the museum gift shop. Also I could not leave without buying some nibs, including a set with two pen holders and a vintage-looking tin. There were few fountain pens for sale. I could have bought a Manuscript Clarity, demonstrator pen, but I already have two of them.

Needless to say, I found that using a dip pen can be a frustrating business, the nibs being scratchy and needing to be dipped frequently. It was a relief to pick up a reliable, smooth fountain pen again. But having been inside this former factory, where hundreds of people laboured, from 160 years ago, I have a new appreciation for the art of pen making and the pioneering work to industrialise the process.

The Pen Museum were happy for me to take photographs and use them in my blog. As the museum is run by volunteers and has limited opening times and visitor capacity, booking is recommended, at http://www.penmuseum.org.uk. Tickets are £7.50 for adults.

Don’t forget the Birmingham Jewellery Quarter is also home to Yard-O-Led and also the Royal Jeweller, maker of the pen we saw at the Coronation and also apparently (tbc) the maker of Onoto sterling silver pens.

LikeLiked by 1 person

Thanks Gary. It would be fascinating to visit the Yard-O-Led workshops but as far as I know, they are not open to the public.

LikeLike

It’s interesting that some dip nibs are able to write elongated sentences. Whilst some will not finish a single letter. Also, some are really smooth on the paper whilst others dig in. I have about a dozen favourite dip nibs that are a joy to write with. And of course the India/China inks can be experimented with. I tend to pass unused dip nibs, that are vintage, through a candle flame quickly to remove possible protective coating. Also, thinking about different nib choices. The Rotring Graphos interchangeable nibs are a strange phenomena too. Thank you for this interesting write up. Very informative. All the best.

LikeLiked by 1 person

Thank you. I have not used steel dip nibs very much. If you find some which write smoothly for you and which can manage a few lines or more without re-dipping, then it is worth setting those aside. When I got my new nibs home, I tried them all out with some black calligraphy ink. Some worked for me better than others. Some have a dimple to act as a reservoir. Also there are simple, clip-on reservoirs which can be attached to increase capacity.

I had not heard of burning off a nib’s protective coating by passing it over a candle flame. I am reading about the process used in Victorian times. One of the steps that a nib would pass through, was called scouring, which included immersing nibs in an acid solution to remove any traces of grease or other substances picked up by earlier processes. Nibs were then tumbled in a revolving barrel with metal spikes for 12 hours at about 30rpm, with a mixture of dehydrated lime, water and small pebbles, then again with a dry compound and finally with sawdust. This gave the nibs a bright silver colour and a rounded point. This all makes my own practice, of sometimes flushing a new nib and section with water or detergent for a minute or so, to remove oil and grease – sound very amateurish!

I was not familiar with the Rotring Graphos system but a google search led me to your own blog post on this.

LikeLiked by 1 person

Great reply and thank you. I have got my favourites in the very same tin that you have just purchased in the packet seen in your photograph. The dimple is a great design. The little reservoirs are a bit hit and miss depending on nib shape. But if they house well, they elongate ink application fantastically well. I read about the open flame method a while back, but it is advised that a quick pass through is important. The nib can be damaged otherwise. The system you describe by the Victorians sounds brutal on the nib doesn’t it? But it must work well. My recent Montblanc second hand purchase, the 3-44G oblique nib, was put under the same cleaning process you use before the seller sent it out to me. He described his cleaning regime to me. I didn’t know my Rotring blog post was on the Google search. That’s a nice bit of news. All the best.

LikeLiked by 1 person

Thank you for such an informative post. That figure of 18,000 nibs in 10 hours is mind-boggling. The exhibition displays are so creative, too – wouldn’t you love to see something like that pyramid at a pen show?

LikeLiked by 1 person

Thanks Pamela. Yes, these figures were shocking: for some of the processes, I heard even higher daily production figures per operator, over 20,000. Apparently the steel strips to make the “blanks” came in 6 foot lengths. An operator would feed this through the press with the left hand, then pull the handle with the right hand (which held the handle continually). As well as time pressure, they would be under pressure not to leave too much waste steel. It was hazardous work and it sounds horrendous, having to work at such a pace all day long.

I was not aware of Birmingham’s important history in pen manufacture, or that it still has a Jewellery Quarter producing 40% of our jewellery!

LikeLike

Thank you for a fascinating trip into the history of pen-making. How I wish we still had shops like the one that originally sold your Parker 17. I am staggered that one operator was expected to produce 18,000 nibs in a day. In terms of health & safety I dread to think of the accidents that must have happened in those factories. That said, I would love to ‘have a go’ at making my own nib.

LikeLiked by 1 person

Thank you David. We would all like to go back in time and visit Pope’s Pen Corner!

The Pen Museum was a real eye-opener. Some old photographs showed women working at presses, or in row upon row at grinding wheels. This was generally women’s work whereas the men rolled the steel or attended the furnaces. It does make you look at a dip nib with a new appreciation, although nowadays they are machine made.

LikeLike

Great article, thank you. Some years back a friend took me on a quick tour of Birmingham and I also visited the factory where they produced whistles as in football whistles. It is amazing how much Birmingham contributed during the industrial revolution, a very interesting city indeed. Glad you enjoyed it!

LikeLiked by 1 person

Thanks Stefan. I did not know much about Birmingham before this brief visit, and was unaware of the jewellery quarter and the historic pen industry in particular. I gathered that Birmingham’s location, the canal network and the skilled workforce all contributed to its success as an industrial town and later, city. Apparently three times more patent applications were registered from Birmingham than from any other city.

LikeLike

What a find. I enjoyed your exploits manufacturing a nib. I am most confident I would have managed a zig-zag slit. I agree with your comments relating to dip nibs, generally too scratchy for me; however I do use them.

LikeLiked by 1 person

Thanks Danny. I feel that I should persevere with my efforts in using a dip pen occasionally. After all, these were the norm at one time, and the steel nibs were very convenient compared to quills which needed sharpening frequently! We are spoilt these days when we can reach for a fountain pen.

LikeLiked by 1 person

I came across your blog while searching for Jinhao and am thrilled with the love and expertise with which you write. I had received my mother’s Pelikan from 1948, cleaned it completely and used it constantly. I also had two Pelikan pens. But my favourite was a Lamy Safari. Unfortunately, I had to leave them in Germany, which is a great pity. I took my Kaweco Sport with me and bought two Lamy Safari pens here in Ireland. Writing with a fountain pen is something special because you take your time to write. I love my Montblanc biros and the Pelikan for quick notes, but you can only really write with a fountain pen, at least for me. I will definitely check back regularly. Thank you for your texts.

LikeLiked by 1 person