The Montegrappa “Monte Grappa” fountain pen might not be perfect, but mine holds a special place in my heart.

I first purchased one of these, in the pretty lilac colour with 14k gold medium nib, from Harrods in November 2019. It was an impulse buy, for which my conscience later suffered and I took it back a few days later. The story was told in my brief encounter post, for those who like fountain pen love stories.

Then, as the winds of fortune blew in my favour once again, I got a second chance to own one at a very generous discount, from John Hall’s Write Here tables at the London Spring Pen Show of March 2023. John was ceasing to deal with Montegrappa and clearing his remaining stock. If price/value had been an issue for me previously, then it was no longer. John was down to his last one of this model. It was the smart, black version with a 14k gold nib in medium. I came away with a huge grin on my face and a saving of over 50%.

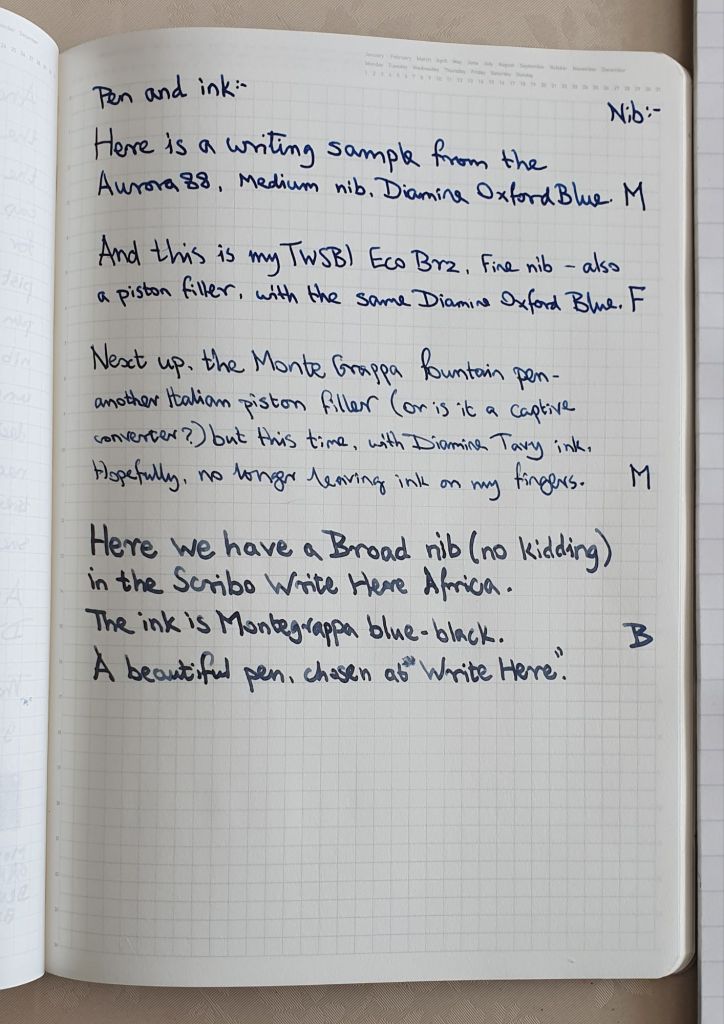

(The Eco is not Italian, but all are piston fillers and the bottom three pens were all purchased from Write Here of Shrewsbury).

At home, I filled it with Diamine Conway Stewart Tavy, my go-to blue black, which immediately became its forever ink. A feature of the pen is the clicky piston filler which sounds and feels like winding a mechanical watch. You cannot see how much ink the pen is holding but can measure it by slowly ejecting the ink again and counting the drops. I am not sure whether purists call this a piston or a captive converter filler. I recall watching a short video from Montegrappa, proudly showing the patented new filling mechanism on its own, and explaining the various different materials that it comprised, (as related in my brief encounter post) but unfortunately I can no longer locate the video. * [see link below].

Picking up this pen after an interval, is always a joy. Its contours and weight all suggest quality, although in terms of Montegrappa’s range of fountain pens, it might be ranked as entry level to the upper echelons. Unusually, it was available with a choice of steel or gold nib.

On re-inking the pen recently I found in the following days, that the pen always left an inky stain on my second finger where I had rested the pen – rather like a smoker’s finger. Despite wiping the section carefully, this continued. I deduced that the ink was coming from behind the flared metal ring at the point where it meets the black resin section. Initially I thought that perhaps the ring had not been glued and sealed sufficiently such that ink would get trapped behind it when dipping in an ink bottle.

To investigate, I flushed the pen and then unscrewed the nib and feed unit. The nib housing simply unscrews from the section. To my surprise, the metal ring then came off the section: it was not glued on at all. (Note: if disassembling a pen over a basin, be sure to have the plug in).

I rinsed and dried all the components. Before reassembling, I took the opportunity to apply some silicone grease around the nib housing and particularly at the ridge where the metal ring is seated. I then screwed the nib housing back tightly into the section, whilst checking that the nib stayed centred over the feed and that the tines were level. I hoped that the combined steps of greasing and tightening the nib housing, would eradicate the inky finger issue.

The pen is now filled, (with Tavy, once again). So far there has been no recurrence of ink on the section.

Such tinkering with a pen on a peaceful Sunday morning is a satisfying activity and to be recommended. It is good to have the Monte Grappa back in rotation. But even when not in use, the remembrance that I own this pen can sometimes be drawn upon to help persuade myself that I do not need more gold nibbed Italian piston fillers. It should be noted however, that this psychology is not always successful.

*Update: I have since found the YouTube video, from Kenro Industries on the Montegrappa Monte Grappa, from six years ago. This featured the piston fill mechanism and can be seen here: https://youtu.be/xgv-FxRnHOU?si=lCtHb2GY-WMQLW-Q

Well written and interesting as usual!

LikeLiked by 1 person

Thanks for reading, Lennart!

LikeLike

I found a similar setup with the front section ring on a Montegrappa Zero, except the ring was press fit on the end of the nib housing. It came free without too much effort. It was somewhat tricky to get it evenly re-seated. I’m sure the factory assembly has a jig that makes it quite simple, but the surfaces where you would apply the force are quite small so I was leery of doing too much and possibly cracking the housing.

Anyway, I was curious why they did it like this. The Zero is cartridge/converter so if using the converter I just remove it to fill separately from the pen, which all but eliminates ink going outside the housing. But having the ring not strongly fastened or sealed to the section manifested two real concerns on your pen. Leaking ink and lost parts can render a pen unusable, so why build those possibilities into the design?

Your Montegrappa and my Zero are beautiful pens, but I think the front section ring is a legitimate weak point. Seems to me there should be a different or better choice, especially considering what Montegrappas cost across the board.

Regards,

Nathan

LikeLiked by 1 person

Thank you Nathan. It appears that these two models both have a similar metal ring on the section, which is not sealed and is liable to retain trapped ink after filling. You have avoided this by filling the converter out of the pen. This is not an option on the piston-filled Monte Grappa of course. It is difficult to avoid dipping the nib too deeply.

I am hopeful that my greasing and tightening the nib housing and ring may have solved the issue. So far so good!

But I do not understand why the pens were designed this way. Surely the issue was foreseeable and I cannot believe that Montegrappa would not want their pens leaking ink on their customers.

LikeLike

What an interesting discovery, glad to hear that you have sorted the issue of the ink seepage. I think that the difference between a great pen and an adequate pen is that you are happy to put up with the foibles of a great pen, whereas you’d probably just give up on it if it was a pen you didn’t especially care for. And I love the admission at the end that your attempts at talking yourself out of buying similar pens don’t always work.

LikeLiked by 1 person

Thanks Pamela. I agree, there are some pens worth fighting for and others that we put in the ‘Do not resuscitate’ category. I can well recall spending several days trying to get a Parker 61 Flighter back into health.

I have a few strategies to curb my impulses to acquire more pens. The most effective generally is to consult my wife who knows best, apparently. 🙂

LikeLike

What a lovely pen. I am not familiar with the filler mechanism, if you find the video, please share. When disassembling a pen over a sink, always have the stopper in. I have unfortunately gotten good at disassembling the sink drain and I still have not learned my lesson.

LikeLiked by 2 people

Thanks Danny. I expect many of us have lost pen parts in this way or come close to doing so.

I will search again for that old Montegrappa video about their piston unit and put the link here if I find it.

LikeLiked by 1 person

Hi Danny. I have since found the video and updated my post to add the link.

LikeLiked by 1 person

Very interesting video. The actuation of the filling mechanism most definitely sounds like winding a watch. I am inclined to say yes it is a piston filler.

LikeLiked by 1 person

In my experience, silicone grease is not the best sealing solution. It is unstable in the long term. If you want a much more durable seal, pure beeswax is the ideal solution. I learned this from an engineer friend. He uses it quite successfully for engine seals. In my case, I used it on the liner cap of a Kaweco Perkeo and the leakage problems I was having were solved. I used to use silicone grease and that was a failure. Over time, the ink mixes with the grease.

LikeLiked by 1 person

Regarding the Kaweco Perkeo, I wasn’t really referring to the liner cap, but to the inner section. The feed nib assembly fits under pressure and if you remove it once, you risk cracking the inner section.

LikeLiked by 1 person

Thankyou. That is a good tip.

LikeLike